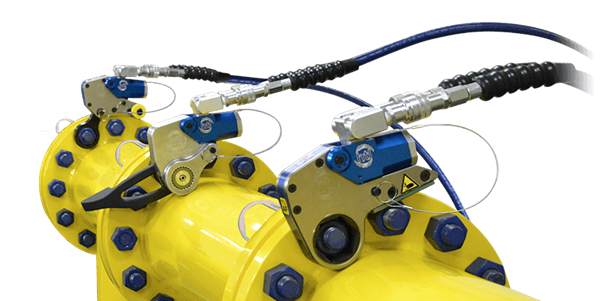

Bolt Torquing & Tensioning

Bolt tensioning is performed by hydraulically stretching a stud to a calculated pre-load value and then hand-tightening a nut.

Bolt torquing is done by using a wrench to turn a nut against a combined resistance created by friction and material elongation. The torque causes the bolt to stretch and creates the required pre-load on the stud.

The main difference is how torquing and tensioning are performed to achieve the desired pre-load. Torquing requires a specific rotational force (torque) to achieve a calculated pre-load, whereas tensioning creates a direct pre-load via hydraulic load cells.

Advantages of tensioning

- Consistent and repeatable results

- Bolting surface finish and lubrication are not a factor in achieving the desired pre-load

- Suitable for larger diameter bolting

Advantages of torquing

- Can be performed with common tools

- Torquing procedures are well understood in the industry

- Typically required on legacy equipment that does not have clearances for hydraulic tensioning